The structure of the straight tube radiant tube: a burner is installed at one end of the straight tube, the gas burns in the tube after the burner is ignited, and the exhaust gas generated by the combustion is discharged from the other end of the tube.

The advantage of this type of radiant tube is that the structure is relatively simple, and the disadvantage is that the temperature distribution uniformity on the surface of the tube wall is poor and the thermal efficiency is low. In the case of stuffy furnace or shutdown,

heat loss will be caused by natural ventilation. On high-temperature industrial furnaces, heat-resistant ceramic material radiant tubes can be used. Two straight-through radiant tubes can be used in pairs.

A waste heat recovery device is installed at the outlet of one tube,

and the other radiant tube preheats the air required for combustion, which can not only improve the temperature distribution of the tube wall surface of the radiant tube, but also improve Thermal efficiency, but inconvenient to install and disassemble.

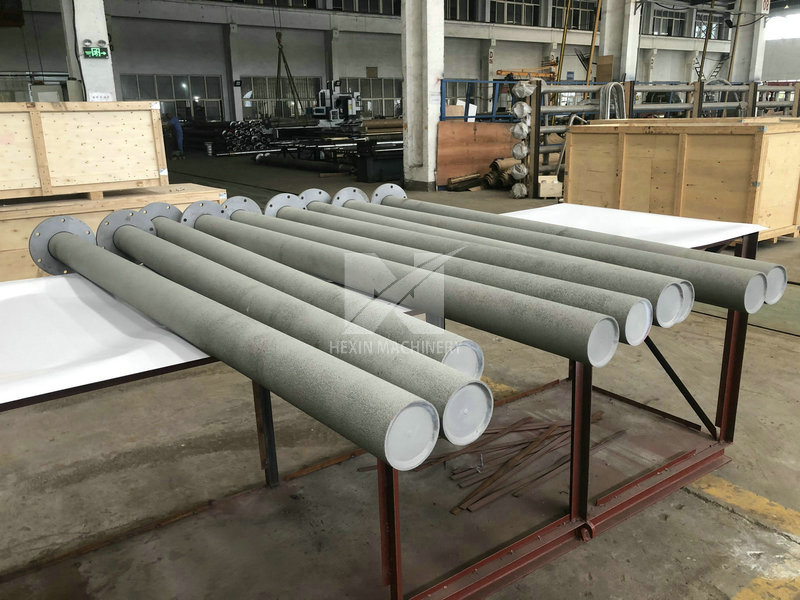

I type radiation tubes wide plate heat treatment furnace radiation pipes used for normalizing furnace, quenching furnace, under protective atmosphere of nitrogen and hydrogen, the furnace temperature is about 500 to 900 ℃, through the heating mode of the burner. Radiant tube by centrifugal casting, under the action of centrifugal force casting the molten steel was casted into a variety of tube. boring hole with the boring machine, welding groove with the lathe machining, and precision casting the bottom end closure.