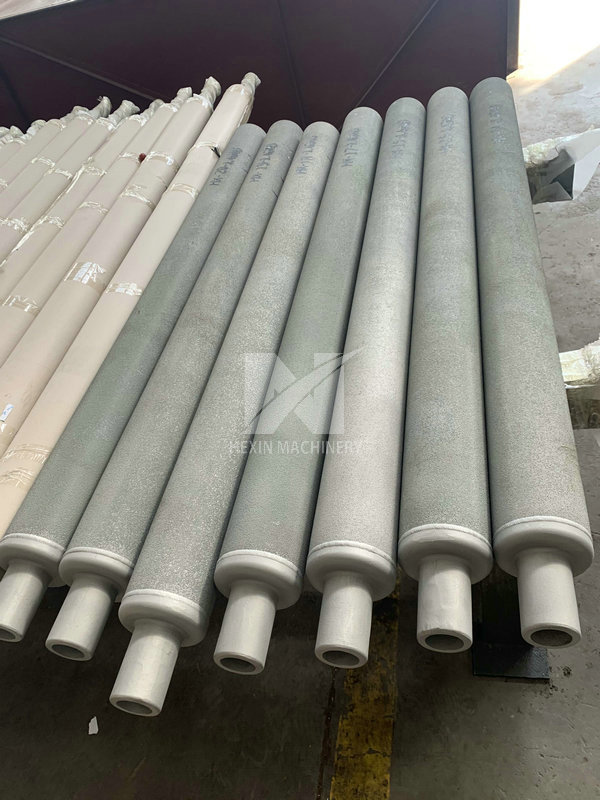

centrifugal cast straight radiant tube

Product Category:Metallurgical IndustryPrice:Negotiation

The main process of the straight tube radiant tube is centrifugal casting. The main straight tube is to inject liquid metal into the high-speed rotating mold, so that the molten metal is centrifugally moved to fill the mold and form a casting.

Due to the centrifugal movement, the liquid metal can fill the mold well in the radial direction and form the free surface of the casting; the cylindrical inner hole can be obtained without a core; it is helpful for the removal of gas and inclusions in the liquid metal;

Influences the crystallization process of metals, thereby improving the mechanical and physical properties of castings.

Centrifugal cast radiant tube, under the action of centrifugal force casting the molten steel was casted into a variety of tube. boring hole with boring machine , welding groove with the lathe machining, and precision casting the bottom end closure, 100% PT inspection.

straight pipe adopt centrifugal casting technology, liquid steel casted into various types of tube blank under the effort of centrifugal force, according to boring internal hole with boring mill, machining and welding according to the drawing.

Commonly used material isZG40Cr25Ni20Si2 、ZG40Ni35Cr25Nb、ZG45Ni48Cr28W5Si2,1.4848,1.4852,2.4879,Flange made by forging and machining,each step was under the strictly quality control, PT100%,RT,PMI,all these is to make sure the offered radiant tube have long usage life.