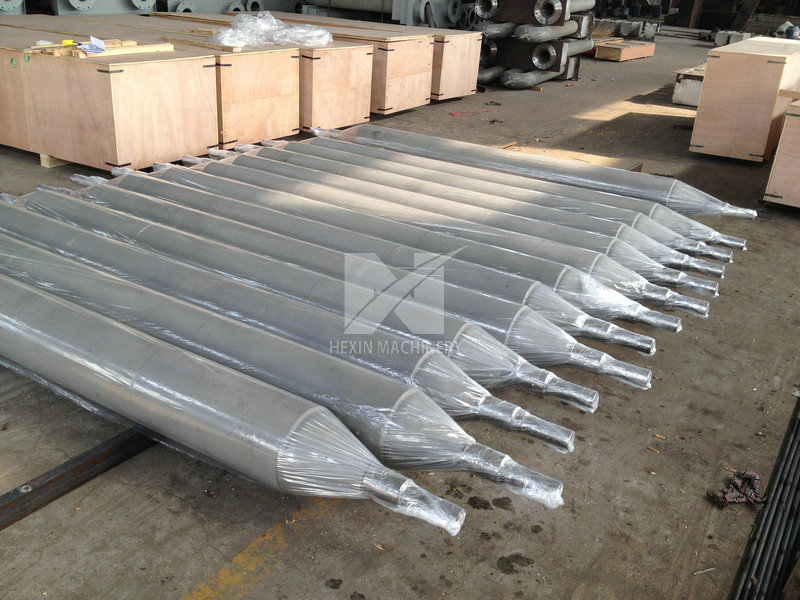

Spun cast rolls for plate heating furnace

Product Category:Metallurgical IndustryPrice:Negotiation

Rolls for roller hearth slab reheat furnaces:

Hearth rollers are indispensable processing equipment in the steel plate smelting and production process to ensure the requirements of steel plate production. The bottom roll is a typical centrifugal casting pipe fitting, and it is one of the important parts for supporting and transporting plates in metallurgical equipment. It is widely used in steel plate continuous casting and rolling production lines.

During the rolling process, the steel billet needs to be continuously and stably heated to the rolling temperature of 1050-1150 ℃ in the furnace first, and the steel billet is stably supported by hearth rollers to ensure smooth and uniform conveying. Since the middle section of the bottom roll is directly installed in the billet calciner, the temperature of the furnace gas during the production process is as high as 1150 °C, and high-temperature alloy materials such as ZG45Cr28Ni48W5Si2 are generally used. At the same time, since the material support part in the middle of the bottom roll is directly installed in the furnace, and the cone section and the bearing support part are respectively installed in the furnace wall and outside the tempering furnace, the temperature gradient of different parts of the bottom roll is very large, therefore, Hearth rolls are generally made by welding cylinders. In order to reduce the combustion loss on the inner surface of the cone, an insulation board is designed inside the cone. In order to ensure the smooth transportation of high-temperature slabs, it is required that the roller shaft is not deformed, and the outer roller ring is heat-resistant and wear-resistant.

The main features of furnace roller products are high temperature resistance, corrosion resistance, wear resistance, impact resistance, easy cutting, welding and so on. Compared with similar heat-resistant steel products, the service life is 1-3 times that of similar products, and the cost is 5%-15% lower than similar materials. It can be used continuously at high temperature and has good heat resistance and high temperature resistance. Good temperature resistance, repeated use is not easy to produce thermal cracks, and the maximum operating temperature can reach above 1400 °C.