Centrifugal casting is suitable for our products

Product Category:Industry NewsPrice:Negotiation

Centrifugal casting is suitable for our products.

Centrifugal casting is a key process in our production process due to its advantageous properties, such as the lack of a core and the wide range of product sizes it can cast. It is particularly suitable for the production of cylindrical products. Products such as radiant tubes, furnace rollers, and small pipes are primarily produced using the centrifugal casting process.

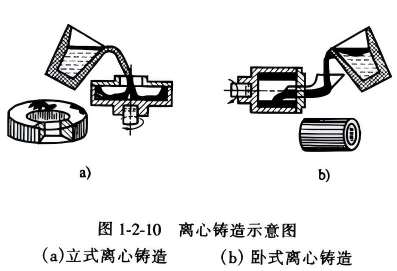

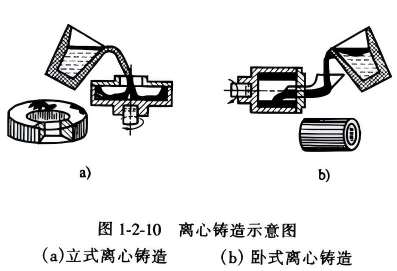

Centrifugal casting, which can be divided into vertical and horizontal centrifugal casting, uses a rotating mold to centrifugally distribute the molten metal and solidify it to produce the casting.

Process Characteristics of Centrifugal Casting:

1. No cores, gating systems, or risers are required, simplifying the structure.

2. Excellent shrinkage feeding conditions result in dense castings with excellent mechanical properties.

Under the centrifugal force, the denser metal is pushed toward the outer wall, while the less dense gas and slag approach the inner free surface, resulting in sequential solidification. This is suitable for single-metal or multi-alloy composite hollow rotating body castings.

3. A wide range of alloys are applicable, with virtually no material restrictions.

4. A wide range of casting sizes is available. Filling capacity ranges from a few tenths of a kilogram to over ten tons, making it suitable for processing metals with poor fluidity or thin-walled parts.

5. Gradient materials can be easily produced, resulting in rough inner walls, large dimensional errors, and concentrated slag and shrinkage cavities.

6. It is not suitable for producing alloys with large density segregation.

Applications of Centrifugal Casting: Primarily used for pipe and tube castings.

Examples include ductile iron water pipes, copper sleeves, cylinder liners, bimetallic steel-backed copper sleeves, heat-resistant steel rollers, seamless steel pipe blanks, and paper machine drying drums. It can also process disc-type castings, such as pump impellers and motor rotors.

Centrifugal casting can be used to produce products primarily made of medium- and high-alloy steels, titanium alloys, and other materials. Functionally gradient materials and composite materials are emerging as new developments in centrifugal casting.