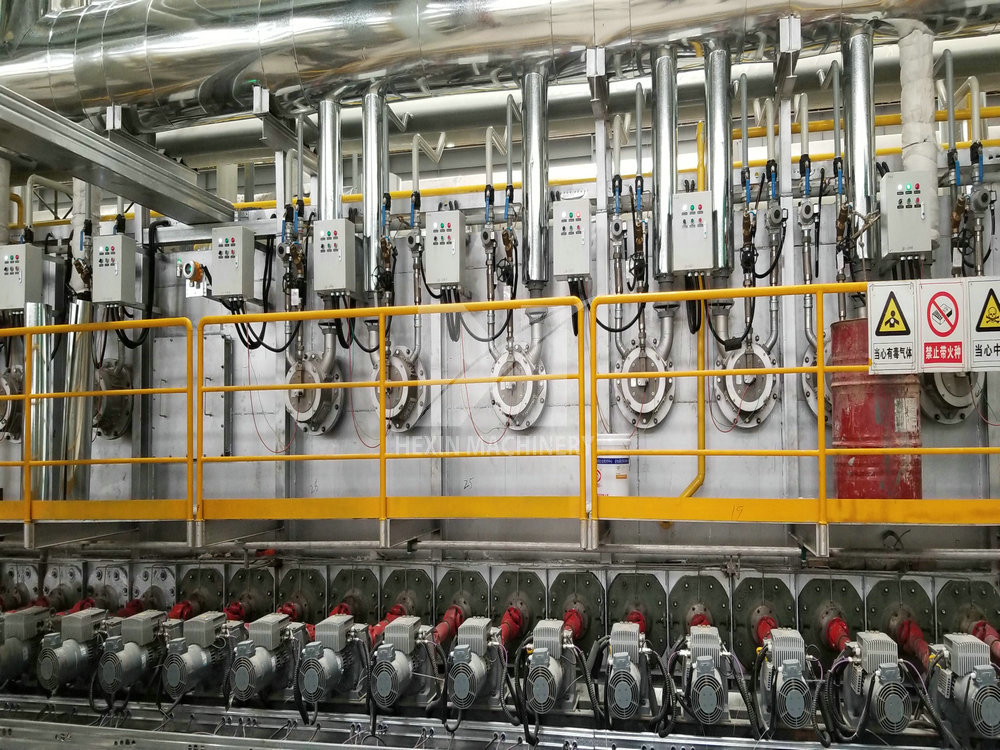

CAL radiant tubes and furnace rollers install

Product Category:Project CasesPrice:Negotiation

CAL continuous annealing furnace roll

The furnace roll is an indispensable equipment in the continuous annealing furnace for strip steel. In order to ensure the continuous operation of strip steel, the continuous annealing furnace roll must have the characteristics of thermal shock resistance, nodulation resistance, good wear resistance, etc., to ensure the normal production and operation of the continuous annealing furnace, so as to ensure the product quality of strip steel. Due to the continuous and stable operation of the continuous annealing unit, the cold rolled products with stable performance and good surface and shape can be produced. Therefore, the furnace roll of the continuous annealing furnace is the core part to ensure the stable operation of the re continuous annealing unit of strip steel.

The strip steel in the annealing furnace goes through the process of temperature rise and fall, so the furnace roll is generally made of Ni Cr heat-resistant steel alloy, and its service temperature is mostly ≤ 900 ℃. Centrifugal casting and static casting processes, combined with forging and finishing, are often used to meet the manufacturing accuracy requirements of furnace rolls. Take the furnace roll in the heating section of the continuous annealing furnace unit as an example. This type of furnace roll is mainly composed of five parts: shaft heads at both ends, two tapered sections, and one section of centrifugal cast pipe. The middle centrifugal cast pipe is made of heat-resistant steel by centrifugal casting process. The two tapered sections are made of static casting process. The shaft heads at both ends are mostly made of forged shafts, and finally made of welding machines. The relevant welds shall be tested by 100% PT, and there shall be no microcrack, slag inclusion, air hole and other defects, otherwise the weld will be cracked during production and use. The assembled and welded rollers also need heat treatment and annealing to remove welding stress.