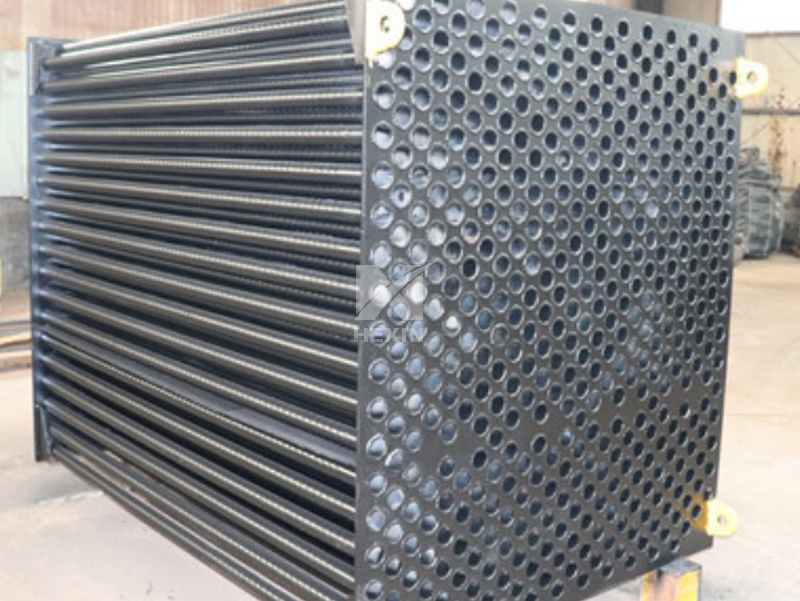

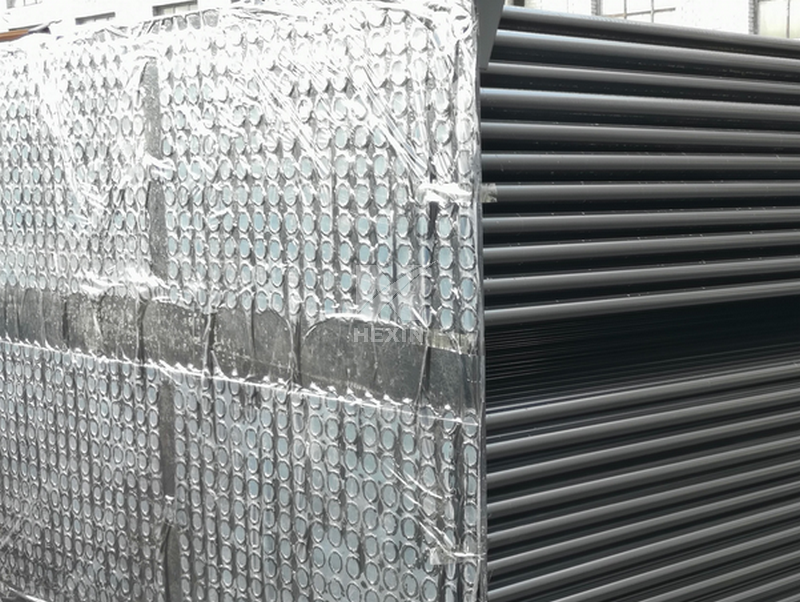

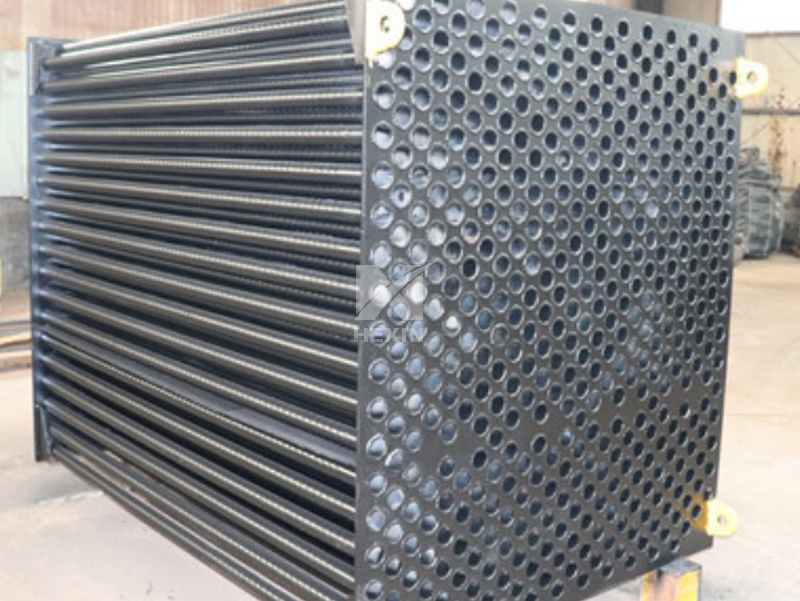

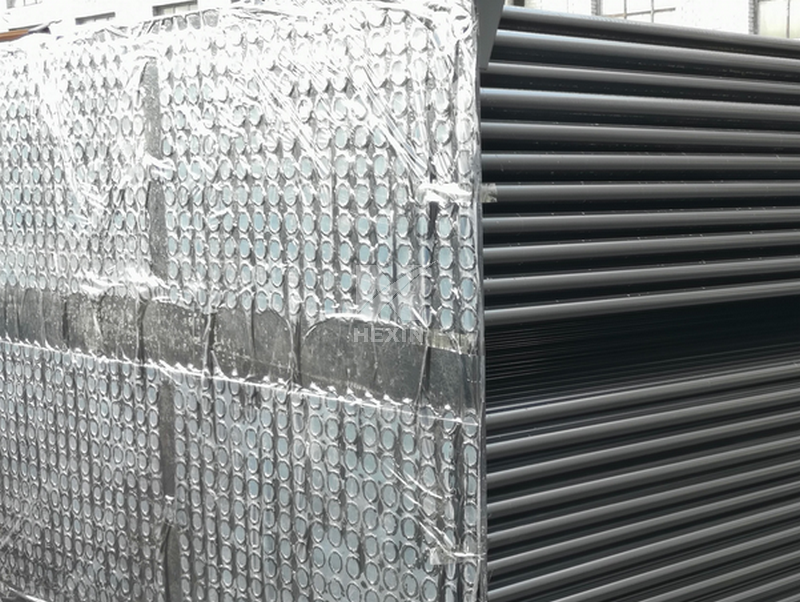

tube bundle spoiler air preheater

Product Category:Petrochemical IndustryPrice:Negotiation

Air preheater, also referred to as air preheater for short, is a preheating device that improves the heat exchange performance of boilers and reduces heat loss. The function of the air preheater is to conduct the heat carried in the flue gas discharged from the tail flue of the boiler to the air before entering the boiler through the heat sink, and preheat the air to a certain temperature.

Generally referred to as air preheater. It is mostly used in coal-fired power station boilers. It can be divided into tube box type and rotary type, and the rotary type is divided into two types: wind cover rotary type and heating surface rotary type. Power plant boilers often use rotary preheaters on the heating surface. The application in the boiler is generally two compartments, three compartments, and four compartments, among which the four compartments are more commonly used in circulating fluidized bed boilers.

The air preheater is generally installed on the tail flue of the boiler, and both the flue gas and the air side use finned tubes for heat exchange to enhance heat transfer performance. Generally, heat pipes are used as heat transfer elements. In order to prevent dew point corrosion and maintain good heat transfer characteristics of finned tubes, a special air preheater consisting of two parts, an evaporator and a condenser, can be used to form a separated phase-change heat system. In this special heat exchanger, the evaporator is located in the lower flue, and the condenser is located above the flue. Both the evaporator and the condenser are composed of finned tube bundles, and each row of tube bundles is interconnected by upper and lower headers.