Walking beam is one of the most commonly used steel coil transportation equipment in rolling mills. The steel coils coming out of the hot rolling coiler are usually transported through walking beams, and then transported to the finished product warehouse through fast chains and slow chains. Walking beams are also used to transport steel coils at the entrance and exit of cold rolling, galvanizing, and even annealing. Walking beams are divided into entrance walking beams and exit walking beams according to different layout positions.

The walking beam is generally located underground, and fixed saddles with a saddle-shaped welded structure are arranged on the walking beam. Each fixed saddle is arranged at a certain distance, and the moving beam will move the steel coil from a fixed saddle every time it runs a cycle. onto the next stationary saddle. The walking beam uses a lifting mechanism and a lateral movement mechanism to realize stepping conveying of materials. In individual cases, stepping can be achieved by an eccentric swivel mechanism.

In modern hot rolling, cold rolling and strip processing line workshops, walking beams are one of the indispensable and important process equipment. All kinds of walking beams commonly used in the iron and steel industry are summarized and analyzed, and the main parameters in the design are calculated. In addition, an optimization scheme of a new type of "T" beam is introduced, which has a good reference value for the selection and design of walking beams.

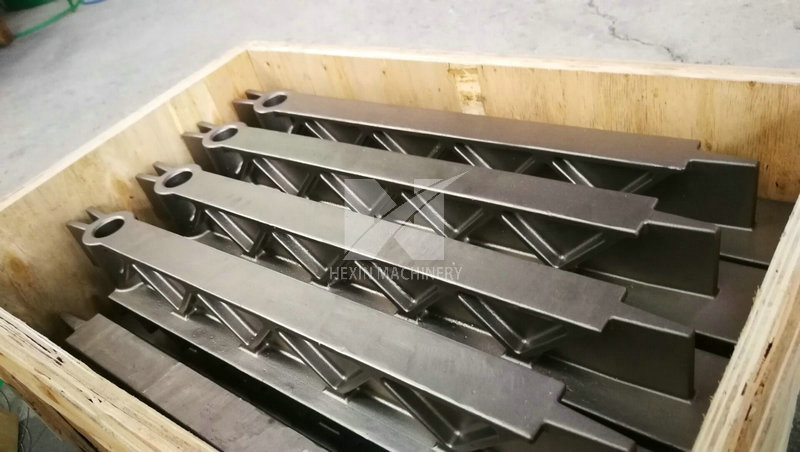

The walking beam is generally made of ZG40Cr25Ni20Si2 material, the maximum operating temperature is 1250 degrees, and the oxidation resistance is good. Material grades such as ZG35Cr25Ni35 and 1.4848 can also be customized according to customer requirements. At the same time, it produces and supplies heat-resistant pallets, brackets, columns and other devices that are matched with this.